John Deere 330LCR Hydraulic Excavator Operators Manual

(TM 5-3805-281-10)

Complete Table of Contents Breakdown:

Section 1: Introduction & Safety

- Safety Messages and Signal Words (DANGER, WARNING, CAUTION, NOTICE)

- Machine Identification (Serial Number Locations, Model Views)

- General Specifications (Operating Weight, Engine Power, Transport Dimensions)

- Component Identification (Major Components: Cab, Undercarriage, Attachments)

- Dimensions and Weights

Section 2: Operation

- Daily Operation Checks (Pre-start, Walk-around Inspection)

- Operator’s Station (Seat Adjustment, Control Console, Monitor Panels, Joystick Functions)

- Starting and Stopping the Engine (Cold/Hot Start Procedures, Shutdown)

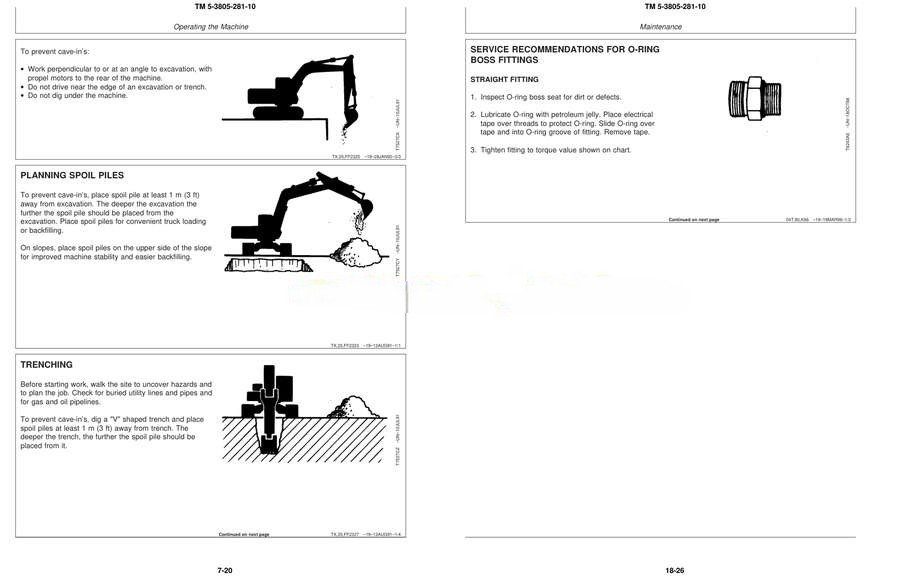

- Machine Operation (Travel, Swing, Excavation, Grading)

- Working with Attachments (Quick Coupler Operation, Hydraulic Circuit Selection)

- Machine Transportation (Loading, Tie-down Points)

Section 3: Engine & Electronic Control System

- Engine Specifications (JD Engine Model, Horsepower, RPM)

- Electronic Control Module (ECM) Overview

- Monitor Panel Functions and Diagnostic Codes

- Engine Diagnostics and Parameters

- Throttle Control System

John Deere 330LCR Hydraulic Excavator Operators Manual

Section 4: Hydraulic System

- Hydraulic System Specifications (Pump Type/Flow, Pressure Settings, Tank Capacity)

- Main Hydraulic Pump (Variable Displacement Piston Pump)

- Control Valves (Main Valve, Pilot System)

- Cylinders (Boom, Arm, Bucket, Swing)

- Hydraulic Motors (Swing, Travel)

- Hydraulic Oil Recommendations and Filtration

Section 5: Electrical System

- Wiring Diagrams (Full Schematic)

- Battery Specifications and Care

- Fuse and Relay Panel Layout

- Sensor Locations (Pressure, Position, Temperature)

- Lighting and Accessory Circuits

Section 6: Undercarriage & Swing System

- Undercarriage Specifications (Track Gauge, Shoe Width, Number of Rollers)

- Track Adjustment and Track Chain Wear Limits

- Swing Gearbox and Swing Bearing (Gear Lash, Bearing Play)

- Travel Motors and Brakes

Section 7: Lubrication, Maintenance & Schedules

- Maintenance Interval Charts (Critical Section – Typically in table format):

- Every 10 Hours/Daily: Walk-around inspection, engine oil level, coolant level, hydraulic oil level, air pre-cleaner.

- Every 50 Hours: Lubricate all pins, linkages, and swing bearing.

- Every 250/500 Hours: Change engine oil and filter, change hydraulic oil filters, clean radiator and coolers.

- Every 1000/2000 Hours: Change hydraulic oil, final drive oil, swing gearbox oil, replace air filter elements.

- Fluid Capacities and Recommendations (Engine oil, Hydraulic, Coolant, Gear Oils)

- Grease Points and Specifications

Section 8: Troubleshooting & Diagnostics

- Structured Diagnostic Outlines:

- Engine Will Not Start (Battery/Starter, Fuel, Electrical Faults)

- Engine Power Loss

- Hydraulic System Issues (Slow Operation, Weak Force, Overheating)

- Electrical System Faults (Monitor Errors, Sensor Failures)

- Abnormal Noise or Vibration

- Diagnostic Trouble Code (DTC) List and Clear Procedures

- Performance Testing (Hydraulic Pressure/Flow Tests, Engine RPM Checks)

Section 9: Storage & Special Procedures

- Long-Term Storage Preparation

- Machine Jacking and Lifting Points

- Bleeding the Fuel System

- Priming the Hydraulic System

Section 10: Appendix

- Torque Specifications for Critical Fasteners

- Beta Values (Service Codes) for Advanced Diagnostics

- Conversion Charts

- Service Dealer Contact Information